The Complete Guide to AOI Inspection Systems: Trends & Yield Optimization (2026)

In electronics manufacturing, precision is the foundation of reputation. As components shrink to 0201 metric sizes and production speeds increase, the margin for error disappears. The AOI Inspection System (Automated Optical Inspection) is no longer just a checker; it is the critical gatekeeper of process control and yield optimization.

For manufacturers in Southeast Asia, particularly in high-growth hubs like Indonesia and Vietnam, understanding modern inline inspection technology is essential for maintaining a competitive advantage. This guide explores the latest trends, standards, and insights into AOI systems from PSI Global Tech.

What is an AOI Inspection System?

An AOI Inspection System is an automated visual inspection tool essential for modern Surface Mount Technology (SMT) lines. It utilizes high-resolution cameras and advanced structured lighting to detect quality defects in Printed Circuit Boards (PCBs) at speeds that manual inspection cannot match.

These systems are strategically placed at critical quality gates:

- Post-Print: To verify solder paste volume and area.

- Pre-Reflow: To check component placement before soldering.

- Post-Reflow: To validate final solder joint quality.

Unlike manual inspection, which is prone to operator fatigue, an automated PCB inspection system operates with consistent precision, scanning for:

- Component presence, polarity, and skew.

- Solder paste quality (volume, height, area).

- Solder joint integrity (shorts, bridging, open circuits).

- Compliance with IPC-A-610 acceptability standards.

Key Trends Shaping AOI Technology in 2025-2026

Basic 2D cameras are no longer sufficient for modern Zero-Defect manufacturing standards. Here are the major technological shifts defining the current generation of inspection systems, such as those from Magic Ray.

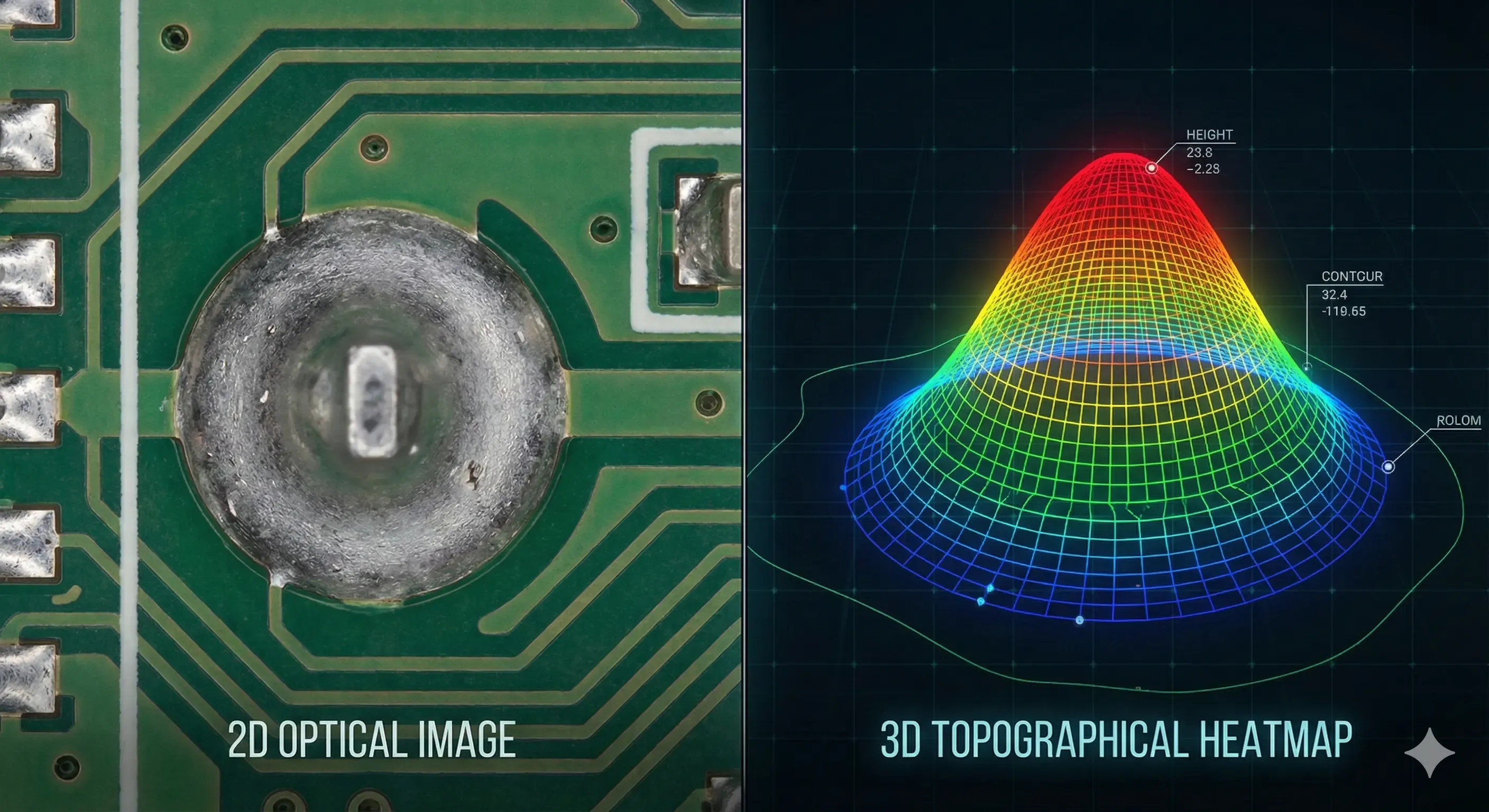

1. The Shift from 2D to 3D Inspection

The most significant industry trend is the migration from 2D to 3D AOI Inspection Systems. Traditional 2D systems often suffer from "geometric blindness", they struggle to distinguish between a valid solder joint and a lifted lead or shadow because they only analyze contrast.

Comparison: 2D vs. 3D AOI Systems

| Feature | 2D AOI System | 3D AOI System (e.g., Magic Ray) |

|---|---|---|

| Inspection Method | 2D Image Contrast & Color Analysis | 3D Profiling & Structured Light Measurement |

| Height Measurement | Impossible (Estimates only) | Precise Height Measurement (Z-axis) |

| Defect Detection | Good for XY alignment, barcodes, OCR | Essential for Lifted Leads, Coplanarity, Volume |

| False Call Rate | Higher (sensitive to lighting changes) | Lowest (based on volumetric data) |

| Best Application | Simple PCBs, Low Component Density | Complex SMT, Automotive, Aerospace |

Advanced systems like the Magic Ray VS7000 series use Ultra-High Range 3D Reconstruction. By projecting structured light and analyzing phase shifts, the machine builds a topographical map of the board, ensuring components meet strict coplanarity requirements defined by JEDEC standards.

2. AI and Deep Learning for False Call Reduction

High false call rates (false positives) cause "alarm fatigue," leading operators to accidentally approve real defects.

Modern inline AOI for SMT lines integrates Artificial Intelligence (AI) and Deep Learning algorithms. Unlike traditional rule-based algorithms, Convolutional Neural Networks (CNN) learn to differentiate between true defects and harmless variations (like flux residue or oxidation colors). This integration significantly reduces false call rates and boosts First Pass Yield (FPY).

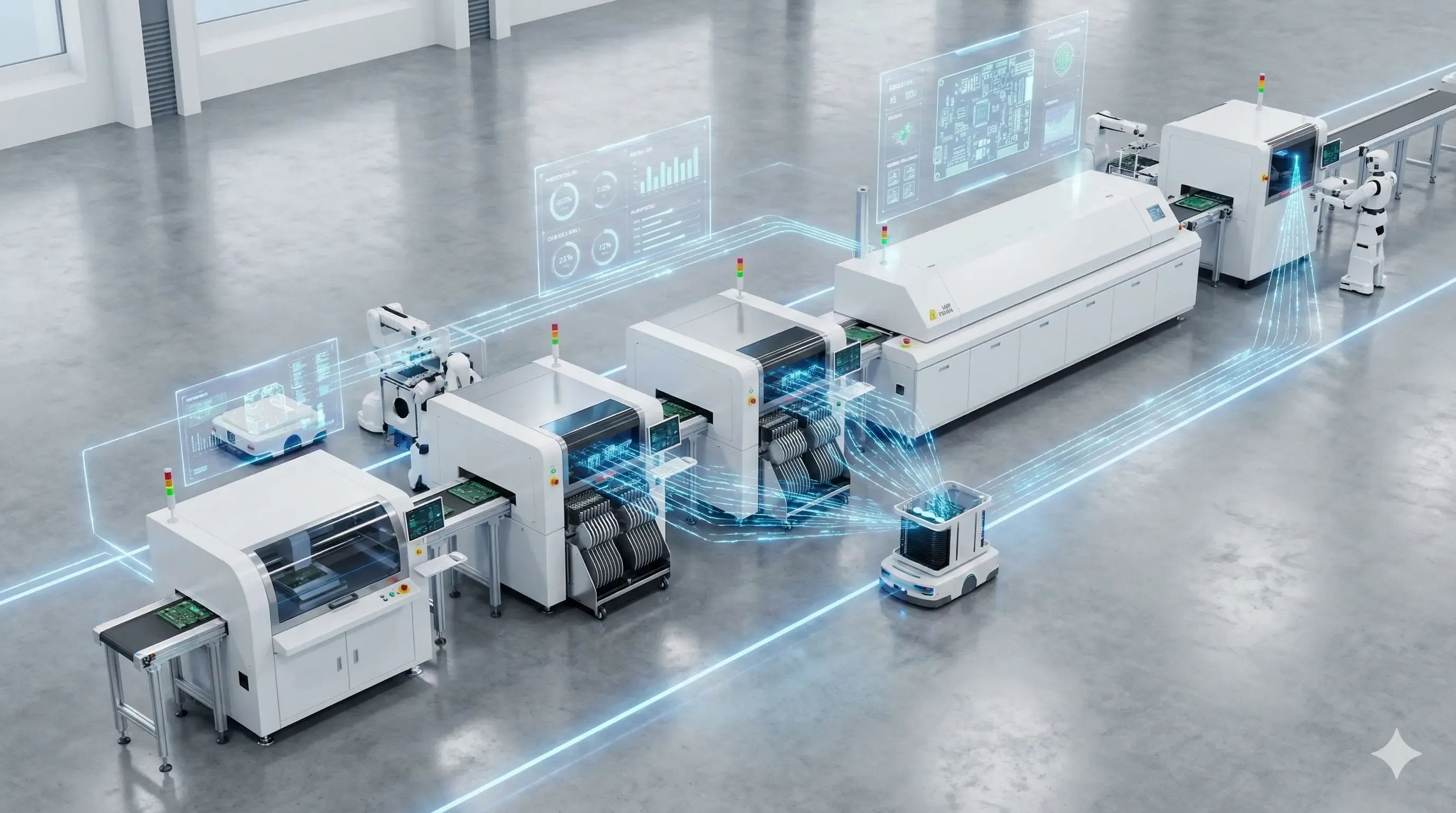

3. Closed-Loop Integration (IPC-CFX)

The modern AOI system does not work in isolation. Through connectivity standards like IPC-CFX (Connected Factory Exchange), it communicates directly with other machines in the SMT line.

- Scenario: If the post-reflow AOI detects components drifting consistently by 0.05mm to the left.

- Action: It signals the upstream Pick-and-Place machine to auto-correct placement coordinates in real-time.

- Result: Prevention of future defects, establishing true process control in SMT.

Why the Zero-Defect Standard Matters

Investing in a premium AOI Inspection System is a financial decision driven by the "Rule of 10." The cost of fixing a defect increases tenfold at each step of the process:

- Post-Reflow: $10 to fix (Rework station).

- In-Circuit Test: $100 to fix.

- Field Failure: $1,000+ plus severe brand damage.

For automotive (IATF 16949) and medical electronics, a robust inspection strategy is mandatory to meet rigorous global safety standards.

Choosing the Right Solution with PSI Global Tech

Selecting the right AOI Inspection System depends on your specific production needs. PSI Global Tech bridges the gap between global technology and local manufacturing needs in Indonesia, Malaysia, and Vietnam.

- For High-End Needs: As an authorized distributor of Magic Ray, PSI offers cutting-edge 3D inline systems capable of inspecting 03015 micro-chips and handling tall components up to 35mm.

- For Cost-Efficiency: PSI provides a trusted marketplace for certified pre-owned equipment, ensuring you get high-performance SMT inspection tools within your budget.

Frequently Asked Questions (FAQ)

Q: What is the difference between Inline and Offline AOI? A: Inline AOI is integrated directly into the conveyor system of the SMT line for 100% automatic inspection at line speed. Offline AOI is a standalone unit where boards are manually loaded/unloaded, typically used for batch testing or smaller production runs.

Q: Can 3D AOI detect lifted leads? A: Yes, 3D AOI is specifically designed to measure height (Z-axis). It can detect lifted leads that are invisible to 2D cameras, which is critical for ensuring reliable electrical connectivity.

Q: How does AOI improve First Pass Yield (FPY)? A: By catching defects early (e.g., post-print or pre-reflow), AOI prevents bad boards from being processed further. Real-time feedback allows operators to adjust the process immediately, reducing scrap and increasing the percentage of good boards produced correctly the first time.

Ready to enhance your production quality? Explore our range of inspection solutions, including the latest Magic Ray 3D systems, at website or contact our technical team for a free consultation on optimizing your SMT line yield.