Refurbished SMT Machines: The Smart Investment Strategy for Electronics Manufacturing in 2026

The electronics manufacturing landscape is entering a new phase of competitive pressure. As we approach 2026, manufacturers face a dual challenge: the need to scale production capacity rapidly while navigating tighter operational budgets.

In this environment, the strategic acquisition of a Refurbished SMT Machine is shifting from a mere cost-saving tactic to a core business strategy. For factory owners in Indonesia, Vietnam, and Malaysia, high-quality pre-owned equipment offers a pathway to expand capabilities without the heavy financial burden of brand-new assets.

Here is why investing in refurbished technology is the smart choice for the future.

Maximizing ROI in a Volatile Market

The primary driver for choosing a Refurbished SMT Machine remains clear: capital efficiency. New surface mount technology lines require massive upfront investment, often taking years to achieve a Return on Investment (ROI).

By purchasing certified refurbished equipment, manufacturers can reduce their initial capital expenditure by 40% to 60%. This financial flexibility allows companies to:

- Allocate budget to other critical areas, such as advanced 3D AOI inspection systems.

- Lower the break-even point for new production projects.

- Maintain healthier cash flow during market fluctuations.

In 2026, where market agility is key, the ability to launch a new line at half the cost is a significant competitive advantage.

New vs. Refurbished SMT: A Strategic Comparison

Making the right choice requires evaluating speed, cost, and reliability. The table below outlines the key differences between acquiring new versus certified refurbished equipment:

| Feature | New SMT Equipment | Certified Refurbished SMT Machine |

|---|---|---|

| Initial Capital Cost | High upfront investment | 40% to 60% lower capital expenditure |

| Lead Time & Deployment | Unpredictable; often several months | Often available for immediate delivery |

| ROI Timeline | Long-term (years to achieve) | Accelerated due to lower break-even point |

| Reliability | Factory spec guaranteed | Reliable from day one when rigorously audited and tested |

The "Safe Transaction" Assurance through Rigorous Calibration

Historically, the secondary market was viewed with skepticism due to concerns about quality and hidden defects. However, companies like PSI Global Tech have revolutionized this space by prioritizing transparency and accountability.

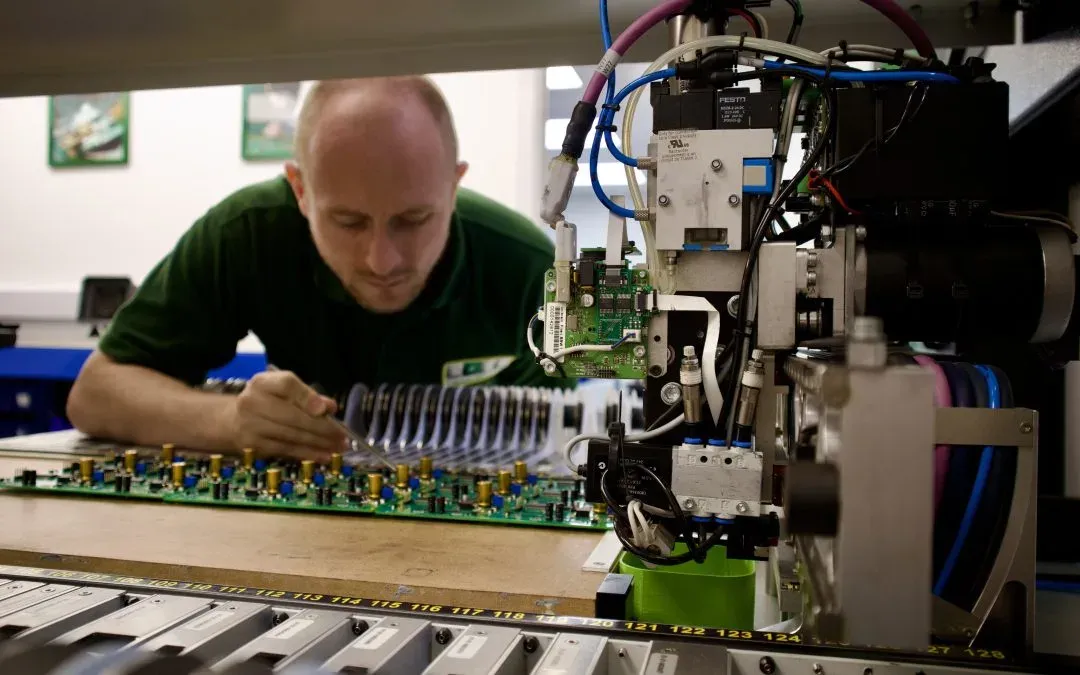

Buying a Refurbished SMT Machine from a trusted partner means you are not buying "as-is" equipment. It involves a rigorous technical process to ensure high yield:

- Auditing & Inspection: Every asset is physically inspected to verify condition and cycle counts.

- Calibration & Testing: Machines undergo functional tests and precise calibration to ensure they meet original factory specifications.

- Transparency: Buyers receive complete documentation and honest assessments of the machine's history.

This commitment to "Safe Transactions" ensures that the equipment performs reliably from day one, removing the risk typically associated with used machinery.

Faster Lead Times and Deployment

Global supply chains for new semiconductor equipment can still face unpredictable delays. Ordering a new high-speed mounter might involve a lead time of several months.

In contrast, a Refurbished SMT Machine is often available for immediate delivery. For manufacturers who need to ramp up production for a sudden order spike or a new contract, this speed is invaluable. You can have a refurbished line installed, calibrated, and running in a fraction of the time it takes to source new equipment.

The Hybrid Strategy: Mixing New and Refurbished

A smart manufacturing strategy for 2026 is the "Hybrid Model." This involves mixing state-of-the-art new technology with reliable refurbished workhorses.

For example, a factory might invest in a brand-new Magic Ray 3D AOI to ensure zero-defect quality control (where inspection technology advances rapidly) while utilizing a robust, Refurbished SMT Machine for the pick-and-place process (where mechanical technology is more stable).

PSI Global Tech specializes in this approach, helping clients build lines that balance peak performance with optimal cost structure.

Sustainability and Green Manufacturing

As global brands increasingly demand green supply chains, sustainability is becoming a business metric. Opting for a Refurbished SMT Machine contributes to the Circular Economy by extending the lifecycle of industrial assets and reducing electronic waste.

By reusing high-quality machinery, manufacturers demonstrate environmental responsibility, which can be a deciding factor for winning contracts with eco-conscious Western clients.

Conclusion

The stigma surrounding used equipment has faded. In 2026, the Refurbished SMT Machine represents agility, financial prudence, and sustainability. It allows manufacturers to scale confidently and profitably.

Ready to optimize your production line? Contact PSI Global Tech today for a consultation or a line audit to find the perfect certified equipment for your needs.

Explore our inventory of certified equipment at www.psiglobaltech.com.